Fluid Bed Catalytic Cracking Unit Manufacturer,Supplier and Exporter in India

Product Code : JA-AM-6492

Jaincolab is a leading Fluid Bed Catalytic Cracking Unit Manufacturer,and suppliers in India, Fluid Bed Catalytic Cracking Unit Manufacturer,and suppliers in South Africa, Fluid Bed Catalytic Cracking Unit Algeria (Algiers), Fluid Bed Catalytic Cracking Unit Angola (Luanda), Fluid Bed Catalytic Cracking Unit Argentina (Buenos Aires), Fluid Bed Catalytic Cracking Unit Armenia (Yerevan), Fluid Bed Catalytic Cracking Unit Australia (Canberra), Fluid Bed Catalytic Cracking Unit Austria (Vienna), Bahrain (Manama), Bangladesh (Dhaka), Bhutan (Thimphu), Bolivia (Sucre), Botswana (Gaborone), Brazil (Brasília), Brunei (Bandar Seri Begawan), Montenegro (Podgorica), Morocco (Rabat), Mozambique (Maputo), Myanmar (Naypyidaw), Namibia (Windhoek), Nepal (Kathmandu), New Zealand (Wellington), Nigeria (Abuja), Oman (Muscat), Palestine (Ramallah), Panama (Panama City), Papua New Guinea (Port Moresby), Paraguay (Asunción), Peru (Lima), Philippines (Manila)¸ Portugal (Lisbon), Qatar (Doha), Rwanda (Kigali), Saudi Arabia (Riyadh), Senegal (Dakar), Serbia (Belgrade), Sierra Leone (Freetown), Slovakia (Bratislava), South Africa (Cape Town) (Pretoria) (Bloemfontein), South Sudan (Juba), Spain (Madrid), Sri Lanka (Sri Jayawardenepura Kotte) (Colombo), Sudan (Khartoum), Syria (Damascus), Tanzania (Dodoma), Thailand (Bangkok), Togo (Lomé), Tonga (Nuku'alofa), Trinidad and Tobago (Port of Spain), Tunisia (Tunis), Turkey (Ankara), Turkmenistan (Ashgabat), Uganda (Kampala), United Arab Emirates (Abu Dhabi), United Kingdom (London), United States (Washington, D.C.).

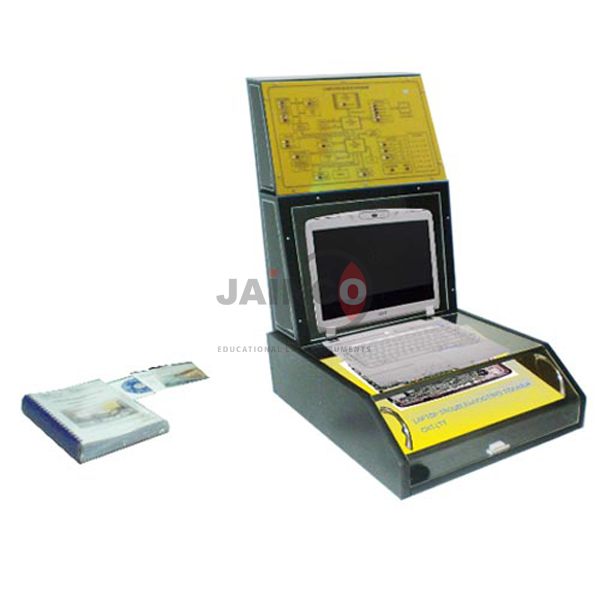

Fluid Bed Catalytic Cracking Unit

Dimensions:

- Base enclosure : 30 1/2 x 21 x 14

- Reactor and Riser : 29 high

- Reactor diameter : 3

- Regenerator : 21 high

- Regenerator diameter : 4

- The model consists of a reactor, regenerator, standpipes, risers and air blower which forms the catalyst circulation system.

- The catalyst flow is controlled by the valves on the reactor and regenerator standpipes.

- Circulation fluidizing of the catalyst is achieved by injecting air into the air inlet of the regenerator, steam inlet of the stripper and the feed inlet to the reactor riser, and is controlled by three individual needle valves.

- Evaluations of start up, operation and shut down procedures in JAab units can be invaluable to industry and educators.

- Demonstrations of catastrophic events may be safely simulated.