Gas Flow Classification Manufacturer,Supplier and Exporter in India

Product Code : JA-AM-6480

Jaincolab is a leading Gas Flow Classification Manufacturer,and suppliers in India, Gas Flow Classification Manufacturer,and suppliers in South Africa, Gas Flow Classification Algeria (Algiers), Gas Flow Classification Angola (Luanda), Gas Flow Classification Argentina (Buenos Aires), Gas Flow Classification Armenia (Yerevan), Gas Flow Classification Australia (Canberra), Gas Flow Classification Austria (Vienna), Bahrain (Manama), Bangladesh (Dhaka), Bhutan (Thimphu), Bolivia (Sucre), Botswana (Gaborone), Brazil (Brasília), Brunei (Bandar Seri Begawan), Montenegro (Podgorica), Morocco (Rabat), Mozambique (Maputo), Myanmar (Naypyidaw), Namibia (Windhoek), Nepal (Kathmandu), New Zealand (Wellington), Nigeria (Abuja), Oman (Muscat), Palestine (Ramallah), Panama (Panama City), Papua New Guinea (Port Moresby), Paraguay (Asunción), Peru (Lima), Philippines (Manila)¸ Portugal (Lisbon), Qatar (Doha), Rwanda (Kigali), Saudi Arabia (Riyadh), Senegal (Dakar), Serbia (Belgrade), Sierra Leone (Freetown), Slovakia (Bratislava), South Africa (Cape Town) (Pretoria) (Bloemfontein), South Sudan (Juba), Spain (Madrid), Sri Lanka (Sri Jayawardenepura Kotte) (Colombo), Sudan (Khartoum), Syria (Damascus), Tanzania (Dodoma), Thailand (Bangkok), Togo (Lomé), Tonga (Nuku'alofa), Trinidad and Tobago (Port of Spain), Tunisia (Tunis), Turkey (Ankara), Turkmenistan (Ashgabat), Uganda (Kampala), United Arab Emirates (Abu Dhabi), United Kingdom (London), United States (Washington, D.C.).

Gas Flow Classification

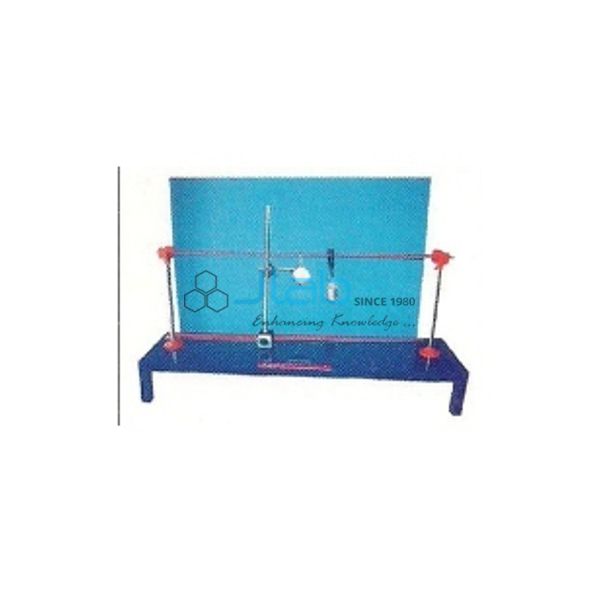

- Zigzag sifters permit classification of solid compounds.

- The solid compound being separated is charged into the feed hopper.

- The compound is fed into the zigzag duct of the sifter at mid-height by way of a vibrating trough.

- An air stream flows upwards through the vertical duct.

- Depending on the geometry and density of the particles, they are carried along by the air or drop down due to gravity.

- At every bend in the duct the solid compound passes through the air stream and falls onto the opposite wall of the sifter.

- This corresponds to one sifting stage.

- Owing to the flow conditions, a vortex wake is formed between two bends of the zigzag duct.

- It ensures that the solid matter moves roughly perpendicular to the airflow.

- In this way, a transverse sift takes place at every bend.

- Sequencing of large numbers of such stages results in very fine separation.

- Features a 20-stage zigzag duct.

- Transparent material provides optimum observation of the processes in the duct.

- A fan generates the airflow.

- The airflow rate and the solid mass flow are adjustable.

- The fine material transported upwards with the air stream is separated by a cyclone.

- Pressure measurement points at the relevant positions in the trainer enable to determine the pressure loss.

- Sand in different particle sizes is recommended for use as the feed material.

- For particle size analyses of the feed and of the coarse and fine material, a balance and a screening machine are recommended.

- The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.