Multi-Process Control Trainer Manufacturer,Supplier and Exporter in India

Product Code : JA-AM-6476

Jaincolab is a leading Multi-Process Control Trainer Manufacturer,and suppliers in India, Multi-Process Control Trainer Manufacturer,and suppliers in South Africa, Multi-Process Control Trainer Algeria (Algiers), Multi-Process Control Trainer Angola (Luanda), Multi-Process Control Trainer Argentina (Buenos Aires), Multi-Process Control Trainer Armenia (Yerevan), Multi-Process Control Trainer Australia (Canberra), Multi-Process Control Trainer Austria (Vienna), Bahrain (Manama), Bangladesh (Dhaka), Bhutan (Thimphu), Bolivia (Sucre), Botswana (Gaborone), Brazil (Brasília), Brunei (Bandar Seri Begawan), Montenegro (Podgorica), Morocco (Rabat), Mozambique (Maputo), Myanmar (Naypyidaw), Namibia (Windhoek), Nepal (Kathmandu), New Zealand (Wellington), Nigeria (Abuja), Oman (Muscat), Palestine (Ramallah), Panama (Panama City), Papua New Guinea (Port Moresby), Paraguay (Asunción), Peru (Lima), Philippines (Manila)¸ Portugal (Lisbon), Qatar (Doha), Rwanda (Kigali), Saudi Arabia (Riyadh), Senegal (Dakar), Serbia (Belgrade), Sierra Leone (Freetown), Slovakia (Bratislava), South Africa (Cape Town) (Pretoria) (Bloemfontein), South Sudan (Juba), Spain (Madrid), Sri Lanka (Sri Jayawardenepura Kotte) (Colombo), Sudan (Khartoum), Syria (Damascus), Tanzania (Dodoma), Thailand (Bangkok), Togo (Lomé), Tonga (Nuku'alofa), Trinidad and Tobago (Port of Spain), Tunisia (Tunis), Turkey (Ankara), Turkmenistan (Ashgabat), Uganda (Kampala), United Arab Emirates (Abu Dhabi), United Kingdom (London), United States (Washington, D.C.).

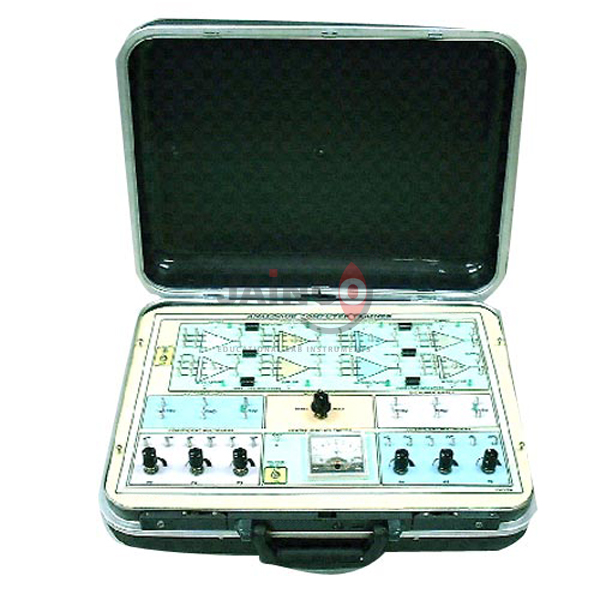

Multi-Process Control Trainer

Technical Description:

- This control trainer is a comprehensive unit featuring only industrial components.

- It contains a transparent tank for liquid-level and pressure control, a corresponding pipe for flow control, and a two-circuit system with a plate heat exchanger for temperature control.

- Alternatively, a pneumatically operated control valve or a speed-controlled pump is used as an actuator.

- The parameters of the digital controller can be adjusted over wide ranges so that a large number of different process conditions can be investigated.

- Electronic sensors measure the individual process values.

- A three-channel recorder with current inputs is included for recording the control behavior over time.

Learning Objectives / Experiments:

- Introduction to the layout and function of a control loop.

- Open and closed control loop.

- Critical amplification.

- Liquid-level control.

- Flow control.

- Pressure control.

- Temperature control.

- Cascade control: level-flow, temperature-flow.

- Different actuators: control valve, pump with variable speed.

- Defining the parameters of a controller after JAab.

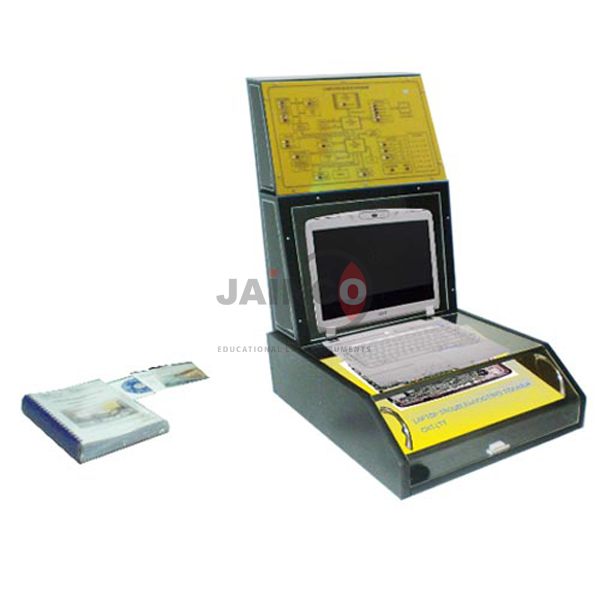

Features:

- Industrial microprocessor-based controller with free parameter setting; 4 controlled variables.

- Continuous, on-off and cascade control.

- Usage of standard industrial components.

- 3-channel chart recorder.

- Process control software optionally available.