Process Training Unit Manufacturer,Supplier and Exporter in India

Product Code : JA-AM-6489

Jaincolab is a leading Process Training Unit Manufacturer,and suppliers in India, Process Training Unit Manufacturer,and suppliers in South Africa, Process Training Unit Algeria (Algiers), Process Training Unit Angola (Luanda), Process Training Unit Argentina (Buenos Aires), Process Training Unit Armenia (Yerevan), Process Training Unit Australia (Canberra), Process Training Unit Austria (Vienna), Bahrain (Manama), Bangladesh (Dhaka), Bhutan (Thimphu), Bolivia (Sucre), Botswana (Gaborone), Brazil (Brasília), Brunei (Bandar Seri Begawan), Montenegro (Podgorica), Morocco (Rabat), Mozambique (Maputo), Myanmar (Naypyidaw), Namibia (Windhoek), Nepal (Kathmandu), New Zealand (Wellington), Nigeria (Abuja), Oman (Muscat), Palestine (Ramallah), Panama (Panama City), Papua New Guinea (Port Moresby), Paraguay (Asunción), Peru (Lima), Philippines (Manila)¸ Portugal (Lisbon), Qatar (Doha), Rwanda (Kigali), Saudi Arabia (Riyadh), Senegal (Dakar), Serbia (Belgrade), Sierra Leone (Freetown), Slovakia (Bratislava), South Africa (Cape Town) (Pretoria) (Bloemfontein), South Sudan (Juba), Spain (Madrid), Sri Lanka (Sri Jayawardenepura Kotte) (Colombo), Sudan (Khartoum), Syria (Damascus), Tanzania (Dodoma), Thailand (Bangkok), Togo (Lomé), Tonga (Nuku'alofa), Trinidad and Tobago (Port of Spain), Tunisia (Tunis), Turkey (Ankara), Turkmenistan (Ashgabat), Uganda (Kampala), United Arab Emirates (Abu Dhabi), United Kingdom (London), United States (Washington, D.C.).

Process Training Unit

- The Process Trainers are “hands-on” training units for process operators and maintenance technicians.

- The units are built to duplicate “real world” operating equipment and consists of separate functions all integrated into a compact, effective training unit in order to train personnel in the process industry in a safe manner.

- The units consist of the following component sections:

- Pumps – There are two ANSI process pumps mounted in parallel on the trainer.

- Tanks & Piping – The trainer is equipped with two tanks and associated interconnecting piping. All tanks and piping are stainless steel to minimize corrosion.

- Level Control – The Process Trainer is equipped with a level control loop, which controls the level in the top receiver.

- Pressure Control – The unit is equipped with a pressure control loop.

- Flow Control – The trainer has an orifice flow control loop on it. The flow is controlled to the overhead tank.

- Temperature Control – A temperature control system/loop is provided with the trainer. The system consists of a side stream, which flows through a fixed wattage heater. For safety reasons, the heating unit is equipped with a high temperature shutdown and an overpressure relief valve.

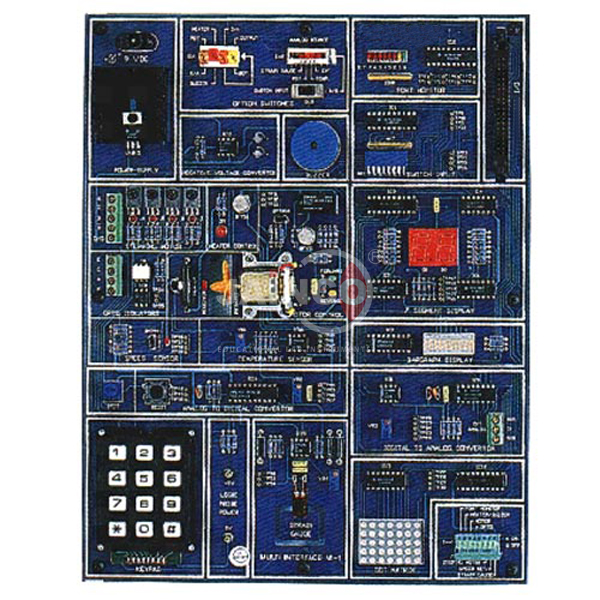

- PLC – The Programmable Logic Controller (PLC). It is integrated to all the control loop functions of the trainer. As received, it is programmed to operate the system, as well as provide cascading abilities between various loops. If desired, it can also be equipped and programmed to provide supervisory interlock functions.

- The Process Trainers are capable of a minimum of 38 specific training and educational functions with an endless number of potential variables for troubleshooting scenarios on piping, valves, flanges, flow, level, pressure, electrical, instrument, pneumatics, It is endless what can be taught on this all around trainer.

- Basic Process Trainers: Total Training Unit

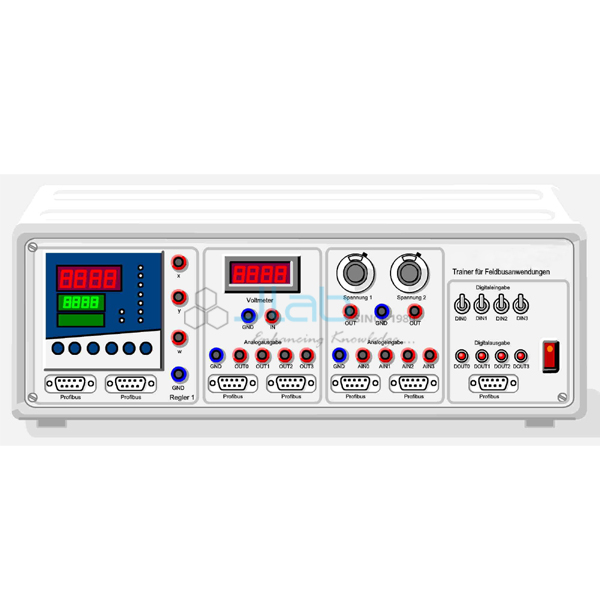

- CTT – Custom Model

- ETT – Educational Model

- CTT-RS – Educational Model W/ Remote Supervision

- CTT-FB – Educational Model W/ Field Bus

- Total Training Unit Add Ons

- PHT – pH Training Module

- DIT – De-Ionization Training Module

- DST – De-Salination