Training System Pressure Control Manufacturer,Supplier and Exporter in India

Product Code : JA-AM-6470

Jaincolab is a leading Training System Pressure Control Manufacturer,and suppliers in India, Training System Pressure Control Manufacturer,and suppliers in South Africa, Training System Pressure Control Algeria (Algiers), Training System Pressure Control Angola (Luanda), Training System Pressure Control Argentina (Buenos Aires), Training System Pressure Control Armenia (Yerevan), Training System Pressure Control Australia (Canberra), Training System Pressure Control Austria (Vienna), Bahrain (Manama), Bangladesh (Dhaka), Bhutan (Thimphu), Bolivia (Sucre), Botswana (Gaborone), Brazil (Brasília), Brunei (Bandar Seri Begawan), Montenegro (Podgorica), Morocco (Rabat), Mozambique (Maputo), Myanmar (Naypyidaw), Namibia (Windhoek), Nepal (Kathmandu), New Zealand (Wellington), Nigeria (Abuja), Oman (Muscat), Palestine (Ramallah), Panama (Panama City), Papua New Guinea (Port Moresby), Paraguay (Asunción), Peru (Lima), Philippines (Manila)¸ Portugal (Lisbon), Qatar (Doha), Rwanda (Kigali), Saudi Arabia (Riyadh), Senegal (Dakar), Serbia (Belgrade), Sierra Leone (Freetown), Slovakia (Bratislava), South Africa (Cape Town) (Pretoria) (Bloemfontein), South Sudan (Juba), Spain (Madrid), Sri Lanka (Sri Jayawardenepura Kotte) (Colombo), Sudan (Khartoum), Syria (Damascus), Tanzania (Dodoma), Thailand (Bangkok), Togo (Lomé), Tonga (Nuku'alofa), Trinidad and Tobago (Port of Spain), Tunisia (Tunis), Turkey (Ankara), Turkmenistan (Ashgabat), Uganda (Kampala), United Arab Emirates (Abu Dhabi), United Kingdom (London), United States (Washington, D.C.).

Training System Pressure Control

Description:

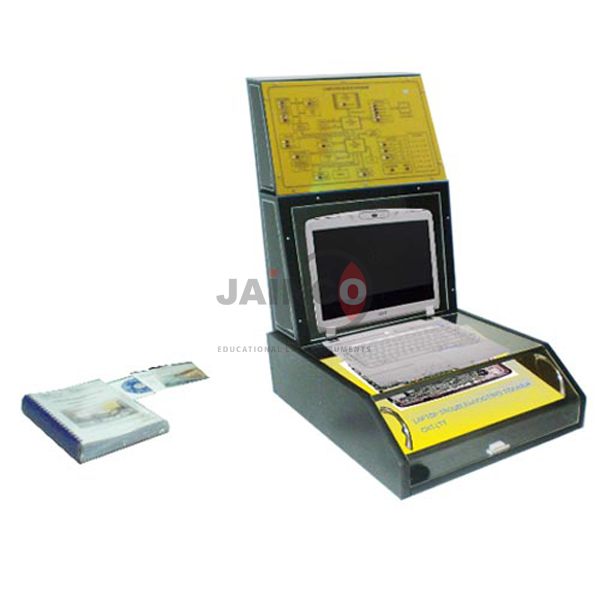

- This compact teaching/training unit offers every opportunity to learn the fundamentals of process control through experimentation on a pressure control system.

- The experimentation set-up is mounted on a solid housing which accommodates all the electronics.

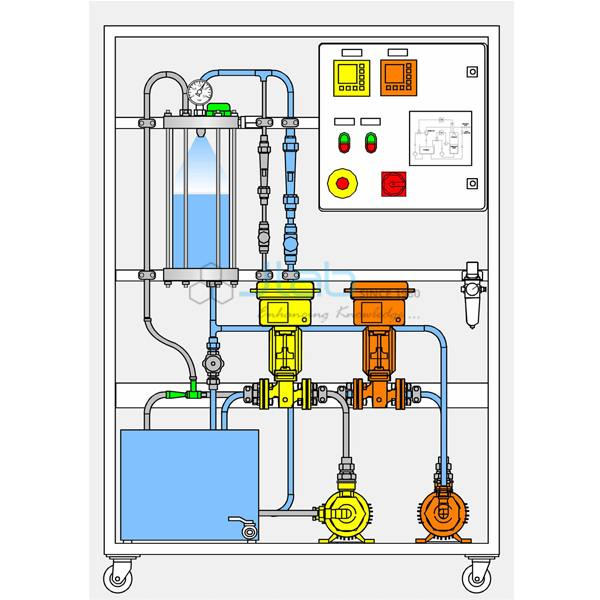

- The process tank is charged with compressed air by a diaphragm gas pump.

- The advantage of the dial-gauge manometer is that the pressure in the tank can be observed directly at any time.

- The pressure is measured using a pressure sensor.

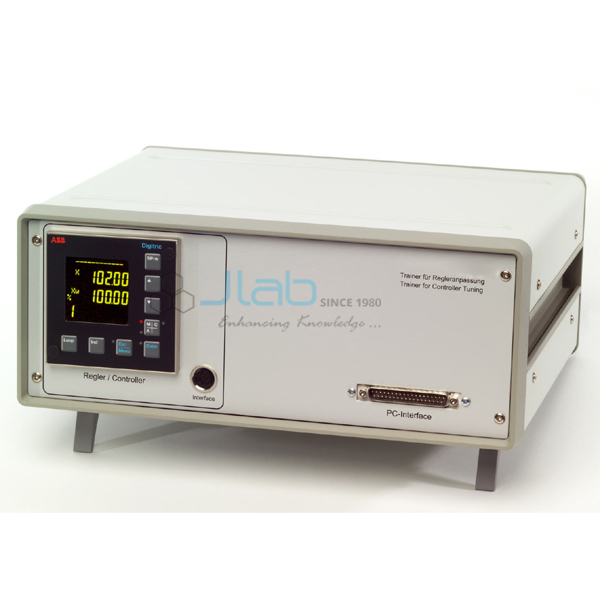

- The sensor output signal is sent to the software controller.

- The output signal from the controller influences the speed of the diaphragm gas pump and hence the delivery flow rate.

- An air consumer is simulated by way of a restrictor valve.

- A solenoid valve through which air can escape can be activated by the software to investigate the influence of disturbance variables.

- The powerful state-of-the-art software is an integral part of the training system, embodying the principle of hardware/software integration (HSI).

- It enables the experiments to be conducted and evaluated in a user-friendly manner.

Diaphragm gas pump

- Max. flow rate: 3L/min

- Max. positive pressure: 1bar

- Max. Negative pressure: 250mbar abs.

Pressure tank

- Capacity: 400mL

- Operating pressure: 1bar

- Max. pressure: 10bar

- Pressure control range: 0...1bar

- Solenoid valve: Kvs: 0,11m³/h

- Pressure transducer: 0...1bar

- Manometer: 0...1bar