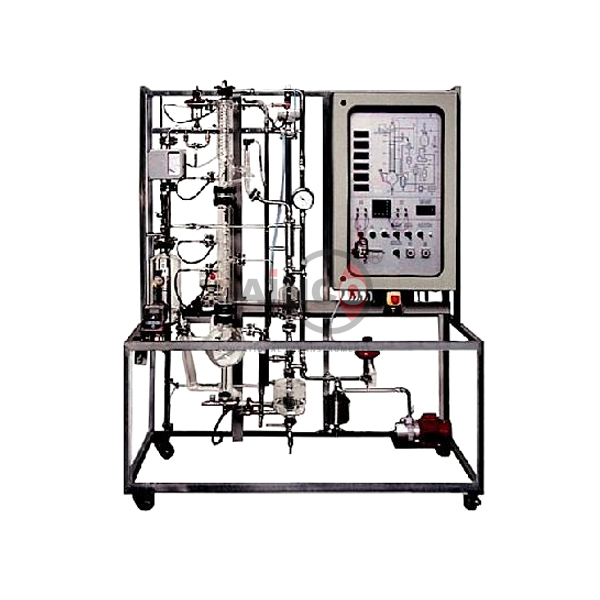

Anaerobic Digester Manufacturer,Supplier and Exporter in India

Product Code : JA-CELE-9113

Jaincolab is a leading Anaerobic Digester Manufacturer,and suppliers in India, Anaerobic Digester Manufacturer,and suppliers in South Africa, Anaerobic Digester Algeria (Algiers), Anaerobic Digester Angola (Luanda), Anaerobic Digester Argentina (Buenos Aires), Anaerobic Digester Armenia (Yerevan), Anaerobic Digester Australia (Canberra), Anaerobic Digester Austria (Vienna), Bahrain (Manama), Bangladesh (Dhaka), Bhutan (Thimphu), Bolivia (Sucre), Botswana (Gaborone), Brazil (Brasília), Brunei (Bandar Seri Begawan), Montenegro (Podgorica), Morocco (Rabat), Mozambique (Maputo), Myanmar (Naypyidaw), Namibia (Windhoek), Nepal (Kathmandu), New Zealand (Wellington), Nigeria (Abuja), Oman (Muscat), Palestine (Ramallah), Panama (Panama City), Papua New Guinea (Port Moresby), Paraguay (Asunción), Peru (Lima), Philippines (Manila)¸ Portugal (Lisbon), Qatar (Doha), Rwanda (Kigali), Saudi Arabia (Riyadh), Senegal (Dakar), Serbia (Belgrade), Sierra Leone (Freetown), Slovakia (Bratislava), South Africa (Cape Town) (Pretoria) (Bloemfontein), South Sudan (Juba), Spain (Madrid), Sri Lanka (Sri Jayawardenepura Kotte) (Colombo), Sudan (Khartoum), Syria (Damascus), Tanzania (Dodoma), Thailand (Bangkok), Togo (Lomé), Tonga (Nuku'alofa), Trinidad and Tobago (Port of Spain), Tunisia (Tunis), Turkey (Ankara), Turkmenistan (Ashgabat), Uganda (Kampala), United Arab Emirates (Abu Dhabi), United Kingdom (London), United States (Washington, D.C.).